Introduction

Industries depend on precision, speed, and consistency. The focus keyword: why is a plastic mold parts manufacturer important for industries becomes essential when discussing modern manufacturing. Plastic mold parts manufacturers help companies create reliable products at scale. These manufacturers provide accuracy, durable molds, and cost-efficiency. In today’s competitive market, their role has become more crucial than ever.

This complete guide explains how these manufacturers support industries, where their importance lies, and what best practices companies should follow. If you want a complete why is a plastic mold parts manufacturer important for industries guide, you can explore helpful insights on AllTopTrend through their internal resource.

Why Plastic Mold Parts Manufacturers Matter for Modern Industries

Plastic molding is a backbone for many sectors. From automotive to consumer electronics, almost every industry uses molded plastic components. Without skilled manufacturers, companies cannot produce consistent, high-quality parts.

A reliable plastic mold parts manufacturer helps industries reduce waste, maintain uniformity, and meet production targets. Their expertise allows businesses to turn raw plastic into precise shapes used in countless applications.

The Role of Plastic Mold Parts Manufacturers in Industrial Production

Precision Engineering

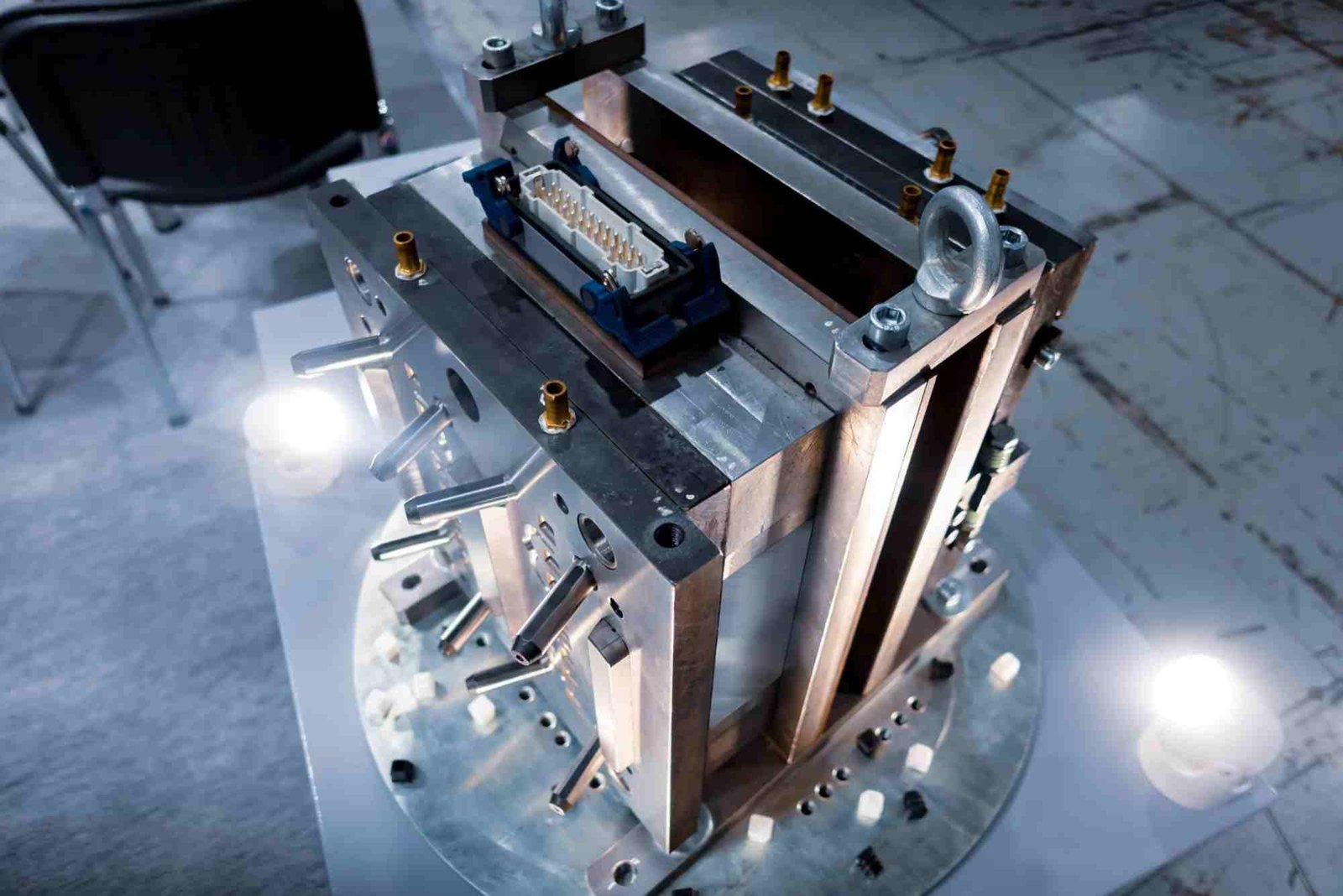

Plastic mold parts manufacturers use advanced technology to create molds with high accuracy. Precision determines product quality. Even a slight misalignment can weaken an entire product line.

Material Knowledge

These experts understand resin types, melting points, durability factors, and suitable molding conditions. Their knowledge ensures every part is made from the right material.

Boosting Mass Production

Industries rely on fast, continuous output. related latest resources Manufacturers design molds that speed up production without losing quality.

How Industries Benefit from Plastic Mold Parts Manufacturers

Consistent Quality

Plastic mold parts manufacturers focus on uniformity. This consistency helps industries build reliable customer trust.

Cost Efficiency

High-quality molds reduce defects. Fewer errors mean lower production costs. Over time, industries save money.

Improved Product Durability

Poor molding results in weak, breakable items. Professional mold creation ensures products last longer and survive real-world conditions.

Faster Design-to-Market Timelines

Quick mold development helps industries launch new products faster. Speed is vital for staying competitive.

Tips for Choosing the Right Plastic Mold Parts Manufacturer

Look for Advanced Technology

A good manufacturer uses CNC machines, automation, and simulation software. These tools reduce mistakes and improve design accuracy.

Check Experience and Portfolio

A manufacturer with diverse past projects brings better solutions. They understand the requirements of different industries.

Ask About Materials

The right manufacturer knows which plastics best suit your applications. They should guide you through resin options.

Compare Lead Times

Timely delivery is important for industrial workflows. Choose a manufacturer that balances speed with quality.

Evaluate Communication

Clear communication prevents errors. Select a partner who understands your needs and provides timely updates.

Common Industries That Depend on Plastic Mold Parts Manufacturers

Automotive

Cars contain hundreds of molded parts. From interior panels to engine components, the industry needs precision.

Electronics

Phones, computers, remote controls, and chargers depend on molded housings and components.

Medical Equipment

Plastic parts must meet strict safety standards. Mold manufacturers ensure compliance and hygiene.

Packaging

Food, cosmetics, and household goods all use molded plastic containers.

Construction

Pipes, fittings, and connectors depend on accurate molding for durability and safety.

Best Practices in Plastic Mold Manufacturing

Prioritize Design Accuracy

Manufacturers must create detailed CAD models before mold creation. Strong design reduces mistakes.

Prototype Before Mass Production

Prototyping ensures the mold works correctly. It also lets industries test functionality.

Use Durable Mold Materials

High-quality steel or alloy molds last longer and withstand repeated cycles.

Conduct Quality Checks

Regular inspections during production prevent flaws and maintain stability.

Follow Eco-Friendly Practices

Recycled plastics and energy-efficient machines reduce environmental impact.

Examples of How Plastic Mold Parts Manufacturers Support Industries

Supporting Automotive Innovation

Electric vehicles need new types of lightweight plastic components. editorial partner Mold manufacturers help create these efficiently.

Improving Medical Device Precision

Manufacturers create molds for syringes, tubes, and diagnostic device housings. These must be uniform and safe.

Enhancing Consumer Electronics

Manufacturers provide exact-fit casings for smartphones and tablets. They protect delicate internal parts.

Streamlining Food Packaging

They create molds for bottles, lids, cups, and containers used in large-volume production.

Challenges Faced by Plastic Mold Parts Manufacturers

Increasing Demand for Custom Components

Industries want unique designs. Custom molds require more planning and advanced tools.

Rising Material Costs

Plastic resin prices fluctuate. Manufacturers must manage costs while maintaining quality.

Environmental Concerns

Industries expect eco-friendly production. Manufacturers must adopt sustainable solutions.

Shorter Product Lifecycles

Manufacturers must design molds quickly as market trends change fast.

Why Is a Plastic Mold Parts Manufacturer Important for Industries Today?

The question why is a plastic mold parts manufacturer important for industries matters more than before. Without these experts, industries would struggle with poor quality, slow production, and inconsistent outcomes. Mold manufacturers make it possible for companies to innovate, scale, and produce dependable items at affordable costs.

They are the foundation behind many products we use daily, supporting both global corporations and smaller businesses.

FAQs

What does a plastic mold manufacturer do?

A plastic mold manufacturer designs and creates molds used to shape plastic into specific parts for different industries.

Why are plastic molds important in manufacturing?

Plastic molds ensure consistency, accuracy, and quality in mass production. They help companies produce identical parts quickly and affordably.

What industries use plastic molds the most?

Automotive, packaging, medical devices, electronics, consumer goods, and construction industries rely heavily on molded plastic components.

How long does a plastic mold last?

A high-quality mold can last from thousands to millions of production cycles, depending on material quality and maintenance.

What should I look for in a plastic mold parts manufacturer?

Look for experience, technical skills, modern equipment, good communication, and fast lead times.

Plastic mold parts manufacturers play a central role in industrial progress. They support mass production, reduce costs, improve product quality, and enable innovation. Understanding why is a plastic mold parts manufacturer important for industries helps businesses make smarter decisions when selecting partners.